HISTORY

De Jong has diversified beyond its traditional product: burners. Embarking on the energy transition and determined to be a leader in the industrial heat space, we have put our money on Hydrogen. Not just with our 100% H2 ready burners, but also with the capability to Turn Key Retrofit your existing installation to a decarbonized and denitrified facility. We have diversified in our process automation offering. And for your Prefab or modularization needs our skid module business supports your needs. De Jong Energy Solutions. World Wide.

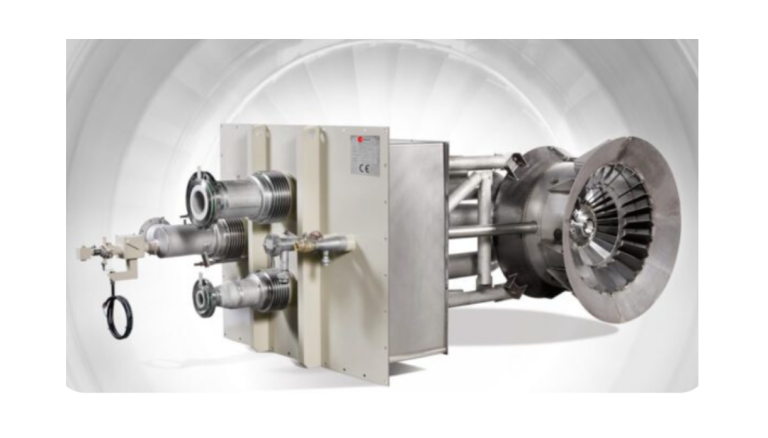

Grid Type Duct Burners

Grid type duct burner is gas-fired and designed for supplementary firing in exhaust gasses from a gas turbine, gas or diesel engine or other industry process flow. Its main function is to increase the temperature and consequently the steam output of a Heat Recovery Steam Generator (HRSG) or Waste Heat Recovery Unit (WRHU). This burner satisfies the need for variable steam demand e.g. between seasons of the year, between periods of the day (for peak shaving purposes) or between stages of the process.

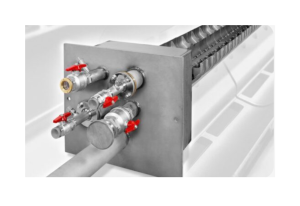

Grid Type Duct Burners

Circular type (R&V) duct burner is gas or oil fired and designed for supplementary firing in exhaust gases from a gas turbine, gas or diesel engine or other industry process flow. Its main function is to increase the temperature and consequently the steam output of a Heat Recovery Steam Generator (HRSG) or Waste Heat Recovery Unit (WRHU). This burner satisfies the need for variable steam demand e.g. between seasons of the year, between periods of the day (for peak shaving purposes) or between stages of the process.

Low NOx Register Burners

Low emissions, high stability: In order to minimize NOx emissions, the burners make use of various proven techniques as combustion air staging, fuel staging, internal flue gas recirculation which have been fine-tuned during several projects. A stable flame is created with consequential low Carbon Monoxide and UHC