HISTORY

PROVALVE has the detailed knowledge required for manufacturing special valves and high-pressure valves in the highest quality whilst keeping price in mind. PROVALVE provides complementary services, which are used all over the globe as follow:

- Comprehensive stocking of standard ASME and DIN valves

- Assembly of valve locking mechanisms

- Assembly of electric drives, e.g. Auma, ROTORK, SIPOS or EMG Assembly of pneumatic drives, e.g. ROTORK, El-O-Matic, SAMSON, AirTorque, STI or as per customer request

- On-site service

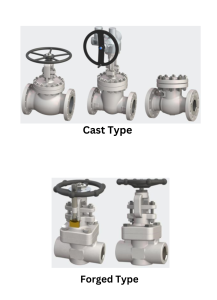

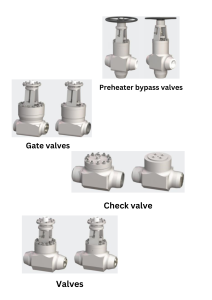

Gates, Valves and Check Valves

- Standard product range of gates, valves, check valves as per API600, ASME standard and DIN in carbon steel, alloyed steel and stainless steel, is available at short notice.

- AD-WO-approved foundries, double material verification and 100% testing for leak tightness and strength all apply to standard products too.

- Some series with fire safe certifications.

High Pressure Valve

- Ideal solution for many critical applications (e.g. steam parameters of up to 625 °C and 365bar).

- Can with stand the fast start-up and shut-down

processes required today and the resultant high loads. - For high-pressure chemicals and petrochemicals,

forged steel high-pressure valves with bolted cover

flanges made of multiple special materials.

Low Temperature Valve

- Gate, valves & ball valves

- For temperatures of -196 °C to 350 °C