HISTORY

The company’s focus from the beginning was to develop, manufacture and sell pneumatic actuators. Over the last 20 years the products have been marketed, outside the Nordic region (Sweden, Norway, Denmark, Finland and Iceland), under the name TruTorq and have been managed through a company in Great Britain.

They made a design with the springs built into the actuator’s pistons; the C-type (C = Classic) was born. This solution gives a compact design which means that actuators with spring return (SR) and double acting (DA) actuators have the same outside dimensions. This compact design was patented.

REXA Xpac Electraulics Actuator

The REXA Xpac Electraulic™ Actuator is a superior positioning device well suited for critical

control applications. The products designed to control severe process conditions in harsh environments and provide high reliability.

Electraulic™ Actuators and Drives provide the final control element capabilities to match the mosts ophisticated instrumentation and distributed control systems.

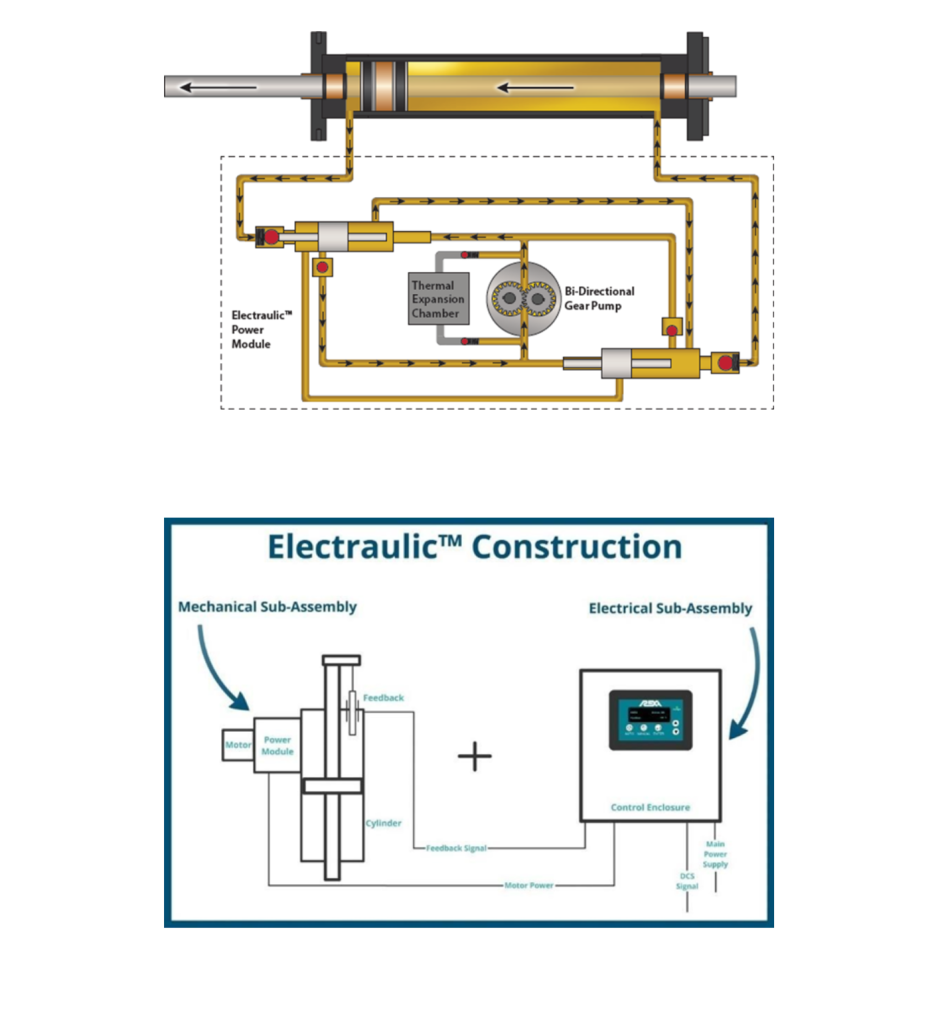

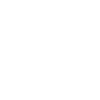

The Xpac is comprised of the mechanical subassembly and the electrical subassembly. The

mechanical subassembly consists of a double acting hydraulic cylinder, position feedback sensor and an Electraulic™ Power Module.

The power module is a unique, self-contained, sealed hydraulic pumping system which manages oil pressure and flow to and from the cylinder. The electrical subassembly consists of the power supplies, motor drivers and a dedicated microprocessor. The combination of these mechanical, hydraulic and electronic technologies gives the Xpac its state-of-the-art capability.

The microprocessor converts the incoming control signal into a target position and compares it to the current position measured by the feedback sensor. If the target position and current position deviation exceeds the user-programmed dead band, the microprocessor will initiate motion to adjust actuator position.

A bi-directional gear pump, driven by an electric motor, generates the hydraulic output necessary to move the actuator. System oil travels from the pump through a series of pilot operated check valves, known as the Flow Matching Valves(FMV’s).

The FMV’s manage oil transfer out of one side of the cylinder and into the other. This drives the actuator to the target position. Once the target position is reached the motor and pump stop, and the FMV’s close, hydraulically locking the cylinder in place. The motor will only turn on again if the signal deviation exceeds the dead band and a position change is required.